All bubbles are not created equally. That does not mean that one method is necessarily better than another, rather the bubbles the different styles of sparkling wine are made through distinctive techniques. The most typical ways that the bubbles can be added to the wine; traditional, tank, and CO2 addition.

Before we can get to the bubbles themselves, we need to discuss the base or still wine. All methods must begin with the base. The winemaker make wine, similar to any other still wine that you are familiar with. The main difference is the timing of the harvest. Typically, fruit destined to be a sparkling wine is picked earlier in the year to guarantee lower brix (sugar levels) and higher acidity. Although Chardonnay and Pinot Noir are most popular as fruit being used, sparkling wine can be made from any grape variety.

Have you been missing the weekly Exploring the Wine Glass posts? They have moved. Sign up below to receive notification of new posts. Subscribe to Dracaena Wines’ blog in the sidebar on this page.

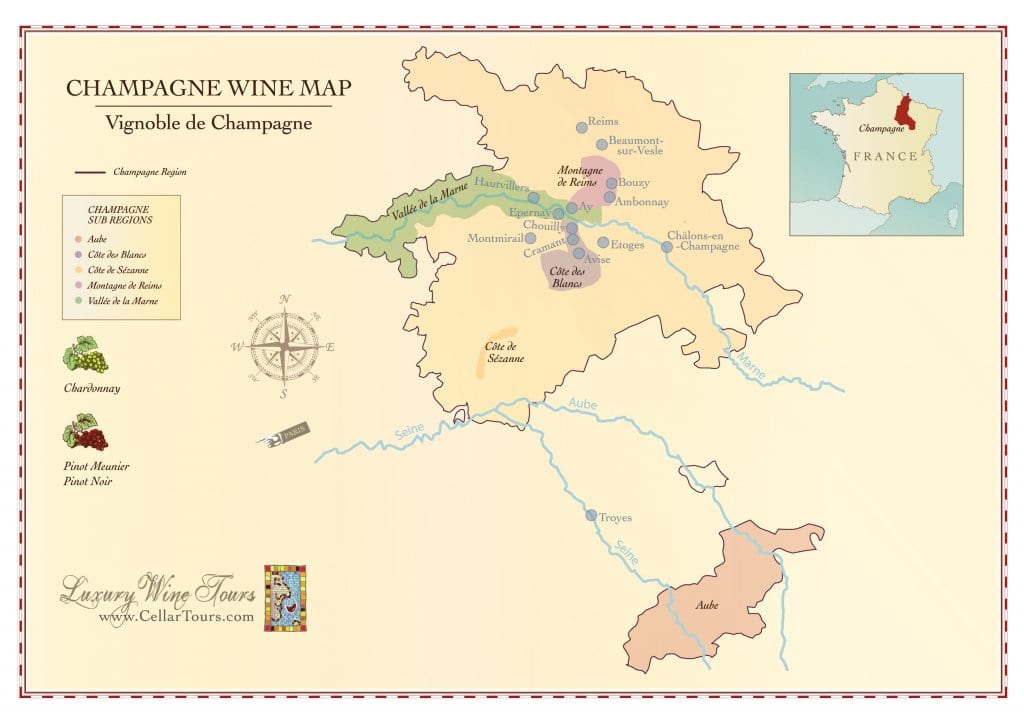

Depending on the region that the wine is made, different varieties are common, even required. For example, in Champagne there are eight permitted varieites that can be grown; Chardonnay, Pinot Noir, Pinot Meunier, Pinot Gris, Pinot Blanc, Petit Meslier and Arbane. The eighth variety, Voltis, is the region’s first authorized hybrid variety.

Similarly to Champagne, the Prosecco region has requisite grape variety; Glera. In order to be labeled as Prosecco, the wine must be made of a minimum of 85% Glera. The remaining 15% can be any combination of Verdiso, Bianchetta Trevigiana, Perera, Glera Lunga, Chardonnay, Pinot Bianco or Pinot Grigio. Cava is usually made from a blend of different grapes. The most common blend is a combination of Xarel·lo, Macabeo and Parellada. But other grapes like Pinot Noir, Chardonnay and Monastrell are allowed. Other regions, like the Loire Valley make their sparkling from Chenin Blanc and Germany’s famous Sekt is Riesling-based. I have personally seen sparkling wine made from Albariño, Counoise, Valdiguié, and Cabernet Franc just to name a few.

All sparkling wine must go through a second step to create the bubbles. We’ll begin with what is deemed as the fastest and least expensive method. CO2 addition. In this method, the carbon dioxide gas is added to the wine to create carbonation. This process is similar to how Coke or Pepsi is made.

Next up in terms of typical bottle cost would be the Charmat method. This process, which is also known as metodo Italiano, the Marinotti method, the tank method, or cuve close gained its name in 1907. Eugène Charmat made improvements on a technique that was invented and patented in 1895 by an Italian named Federico Martinotti. In this method, yeast and sugar are added to a closed tank forcing the second fermentation. The tank is held under pressure so the carbon dioxide from the fermentation is forced into the wine. This process takes between one and six weeks and the atmospheric pressure is around four atmospheres.

The final and most expensive method is known as méthode Champenoise where the second fermentation happens inside the individual bottles in which the wines are sold. The key terminology is within the bottles they are sold. These wines acquire the highest level of carbonation at 6 atmospheres. This method of carbonation originated in the Champagne region of France. Although you can only call a wine “Champagne” if it is produced in the Champagne region, you can make sparkling wine using this method anywhere in the world.

During this process, the base wine is decanted into bottles and fitted with a crown cap. Traditionally, the bottles were then racked horizontally in pupitres, or wooden racks. Traditionally, an individual would rotate the bottles in small increments while gradually tilting it so that it is “neck-down” (“sur pointe”) allowing the lees to travel to the neck. This professional is known as a “remueur” (bottle turner) and is responsible for turning each bottle approximately 25 turns over a 4-6 week period. Today, many wineries have traded using a remueur for a gyropalette. This machine can process metal racks containing 500 bottles in a single operation. Being a machine, it can work longer hours and turn more bottles in a shorter time period. Sadly, in my opinion, a beautiful skilled job disappearing from tradition. After the riddling is complete, all of the sediment will be in the bottle neck, which is then disgorged.

~Slàinte!

Please follow us on Instagram, Twitter, Facebook and Youtube.

We’ve stacked the odds so that you can get our award winning wines without breaking the bank. Click the image to find out all of the benefits of joining the CHALK CLUB including discounted shipping and up to 25% off all purchases. .