It is that season again. Well, actually it is significantly early, but it is the time of year we all get excited about. It’s Harvest Time! When we started the winery, back in 2013, we harvested in November. In 2014, we harvested during Harvest Weekend in Paso Robles. (Oct. 17-19) And this year our Plummer fruit was ready September 24th! Our Still Waters fruit is still taking its time but we are predicting two more weeks which will still be one week earlier than last year. “The Drought” – the excuse for everything- was mentioned countless times. I don’t know what the real reason is for the early harvest, but I can definitely say although early, this year’s fruit is amazing!

We left our house to fly to San Francisco on Thursday at 10:00am. With not being able to get a direct flight without selling our souls, we had a layover in Vegas and finally arrived into Paso Robles at 11:30pm. It was a long day and we were picking our fruit at 4:00am on Friday. I’m not really sure why we even paid for a hotel room. Our heads hit the pillows at around 12:15am and the alarm went off at 3:15am. After a shower and a Starbucks run (thank you for being open 24 hours) we arrived at Plummer’s vineyard and were ready to go.

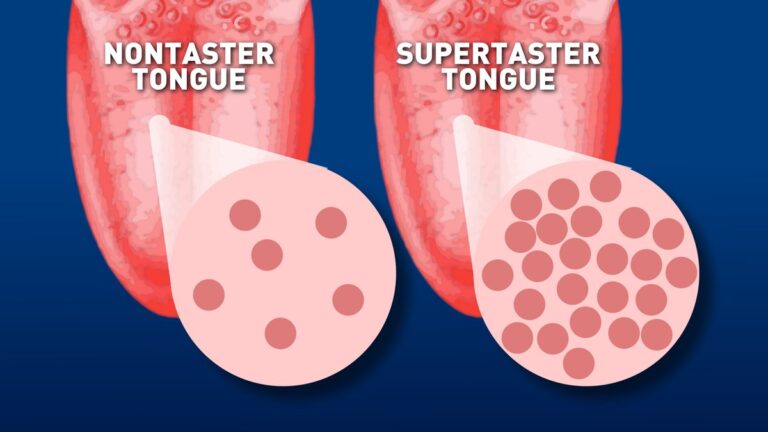

How do we know when the fruit is ready? Mother Nature really decides that, but in general there are a few things that we look for. First there is the Brix level. This is the sugar level within the fruit. As the fruit ripens, more sugar is produced. We also check titratable acidity and pH. These two factors come from the two major acids in the grape, tartaric and malic acid. We also check the seed color which goes from green to brown as they ripen and finally we chew the grapes to make sure the fruit is not bitter and the flavors have developed.

The temperature was pretty cool at 4am but that is why they pick so early in the morning. You don’t want your fruit sitting in the bins after they have been picked while the temperature is 100+ degrees. That is a recipe for microbiological disaster.

We arrived and the crew was already moving in full swing. In this first video you can see how quickly they move through the rows and cut the bunches from the vines. In this second video, you can see how the team works together to get the bunches into the bins and then empty them into the large weighing bins. They work as a well oiled machine and are very efficient. As they move down the rows, all that is left is the cane and the majority of leaves. There are some small bunches that they do not take the time to remove, but for the most part the canes are cut barren from fruit.

[slideshow_deploy id=’2396’]

As a team, they maneuver their way down the rows. One person is on a tractor with two flood lights lighting their way, while two people are on each side of the row cutting and dropping fruit into a small bin. Another person takes the bins when they are filled and dumps them into half ton harvest bins. This harvest was exceptional for us. We were so lucky. While many of the harvests have proven to be light in weight, we actually were heavy. We were expecting one and a half tons and got closer to two. [insert my happy dance here] I am hoping that we get the same results when it is time to harvest the second vineyard.

About two hours later, they were done with our rows and the four bins were brought to the scales. They weigh the fruit at the vineyard so that the vineyard manager gets an estimate of how their vines produced for the year. The fruit was than hauled to the winery where it was weighed again. This is a confirmation weight that get recorded and reported to the Agricultural agencies. This is also the weight that the vineyard owner will get paid by. We finally left the vineyard around 6am. We stopped off for a quick Starbucks run and to take in the beautiful sunrise.

Once we were back at the winery, there was a lot to do. The equipment was cleaned and we began to process the fruit. Processing includes sorting, desteming, a second look to pick out any MOG [materials other than grapes] and then the fruit goes into a fermentation bin. As the fruit is carried into the bin, dry ice is added to keep the fruit cool. Once all the fruit is carried into the fermentation bin, we add more dry ice and the juice will sit on the skins for 48-72 hours. This is known as a cold soak and allows the juice to absorb the color from the fruit skins. After cold soak, we will add the yeast and fermentation will begin. Fermentation can take up to two weeks.

[slideshow_deploy id=’2410’]

The video showing this process can be viewed on our YouTube channel. After fermentation is completed, we will press the fruit and it will go through Malolactic inoculation. MLF will vary in time, but once that is completed, we will transfer to barrels and the wine will mature in them. They will remain in barrel until bottling and be released in 2017.

So now you have experienced a Harvest. If you can, there are many wineries that allow volunteers to help out and it is quite the experience. Jump on it if you can! It is a very exciting [and stressful] time. But it is what wine making is all about.

~Sláinte!